This June will see the arrival of Maersk Line’s new Triple-E vessels, a vessel class designed for Efficiency, Economy of scale and Environmental improvement. The Triple-E vessels will consume approximately 35 percent less fuel and emit 50% less CO2 per container moved, compared to the industry average on the Asia-Europe trade.

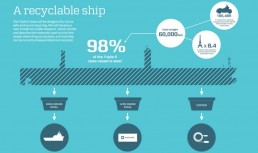

When Maersk Line decided to build the Triple-E ships we also set ourselves a challenge: how can we design the ships to ensure that they can be recycled in a way that preserves the quality of the materials used to build them? For each Triple-E ship we will use approximately 60,000 tonnes of steel, which amounts to 1.2 million tonnes of steel for the twenty vessels in the series, equivalent to 168 Eiffel Towers.

Our response had been to develop a new approach to sustainable shipbuilding and recycling by introducing the most comprehensive material inventory the shipping industry has ever seen, a so-called ‘Cradle-to-Cradle passport’.

Over the past two years we have been working closely together with the shipyard building the Triple-E ships, DSME, and are involving around 75 suppliers to the ship. We have learned from the automotive industry where material inventories became the norm years ago, and we have partnered with other members of the Sustainable Shipping Industry to co-develop ‘closed loop’ material management in shipping.

You can read more about the Triple-E ships here.

And you can read more about the recycling approach here.